Thermal safety is a key issue for all manufacturers of batteries and battery-powered products. The dominant lithium-ion battery (LiB) technology of the current market has been plagued with high-profile public incidents involving battery fires in recent years.

The news has covered everything from exploding hoverboards to melting smartphones and the grounding of Boeing 787 aircraft due to battery fires. Consumers are not the only group at risk, either. There were 23 fires at energy storage installations in South Korea in 2018 and 2019 alone.

Left: Onboard battery fires grounded a Boeing 787.

Right: A hoverboard in thermal runaway exploded at home.

These catastrophic events can be rather terrifying to behold, even from the remote safety of your computer screen. Check out this thermal runaway of an electric scooter inside of a home last New Year’s Eve:

A battery fire due to thermal runaway is both extremely dangerous and incredibly difficult to end once it has begun. Headlines in May of 2021 followed a Tesla Model S crash in Texas that took firefighters 4 hours and 30,000 gallons of water to extinguish.

What Is Thermal Runaway?

A thermal runaway occurs when heat inside of a battery cell ignites the electrolyte. This is a risk whenever the temperature of the battery exceeds a safe operating level. Exothermic decomposition of cell materials will begin and the rate of self-heating can eventually exceed the rate that heat can be dissipated into the surrounding environment. At that point, the cell loses stability, the temperature rises exponentially, the battery cell ruptures, and a fire begins.

Retired NYC firefighter Paul Rogers says, “Once a Li-ion BESS goes into thermal runaway you cannot stop it [in that cell] —your goal is to try to stop the propagation of heat and thermal runaway to adjoining cells.”

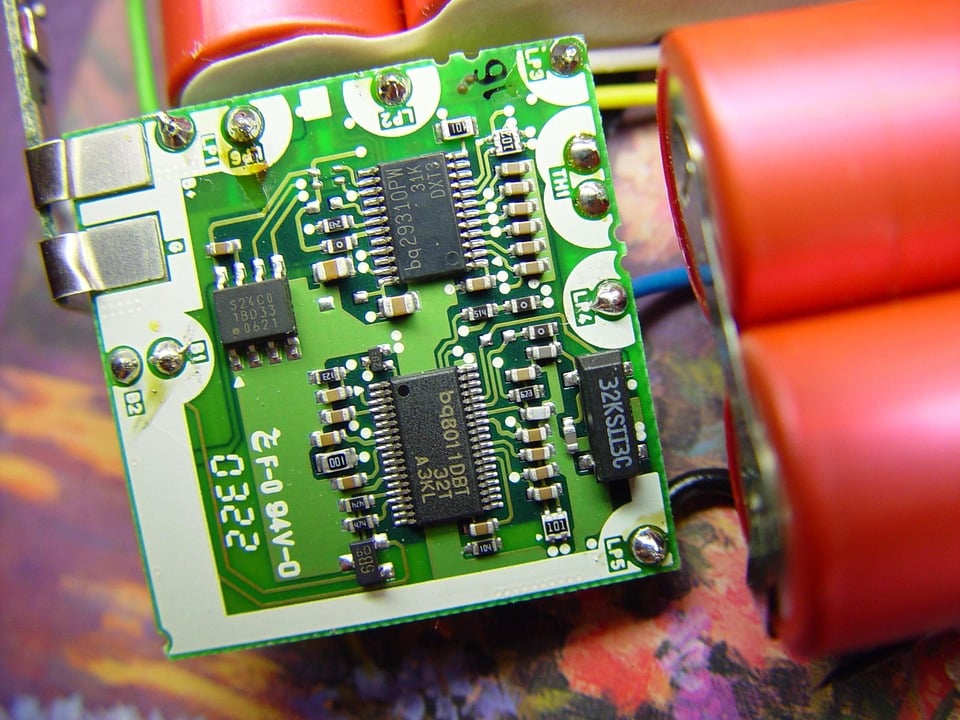

Typically, a thermal runaway risk results from poor manufacturing quality control or design. This can happen when the manufacturer doesn’t fully understand LiB thermal dynamics (or at least, not in the full range of nominal and off-nominal conditions) due to lack of sufficient battery testing and analysis.

Charging batteries and batteries in hot environments are frequent culprits of battery fires. However, damage to the cell’s internal separator materials from improper manufacturing or puncturing by metallic dendrite growth can kick off the process even when the battery is not actively charging or located in a hot environment.

Battery Safety Testing Is Changing…Don’t Fall Behind

As Energy Assurance CEO Cindy Millsaps explained to Battery Power Online, updates to IEC standards are changing test procedures of high-rate capable cells and systems to reflect the growth in fast-charging on formats from phones to EVs. The most current and cutting-edge battery safety testing are necessary to keep products and brands protected and compliant with current technology needs and standards.

It’s no longer enough to trust in basic testing protocols from today’s more expansive range of vendors. EV manufacturers are receiving priority for the lion’s share of available Li-ion batteries from Tier 1 suppliers, in part due to the volume and consistent demand of the automotive industry. This has left many businesses in the consumer electronics, medical, and other spaces to turn to Tier 2 and 3 suppliers that are less thoroughly vetted and may be producing batteries with minimal testing in virtually unregulated environments.

These supply chain disruptions mean it is more important than ever to conduct rigorous battery safety testing to ensure the safety, quality, and reliability of your batteries.

Your Reputation Hangs in the Balance

Battery fires and patterns of thermal runaway frequently lead to urgent product recalls — a costly endeavor that also damages the system manufacturer’s brand reputation in lasting ways. When battery products fail to perform, it’s more than the OEM’s brand that is tarnished, too. Retailers, distributors, and suppliers all stand to lose status as well as future business. Consumers may decide not to purchase from certain websites after receiving faulty products, and OEMs will no longer purchasing parts from the vendors they hold responsible.

If thermal runaway leads to a pattern of severe injuries or worse, the implications can be even greater. The primary method of preventing these events and reducing risks is to perform battery safety testing at every stage of system design, from cell to module to pack.

If you’re looking for an expert partner to facilitate a full array of battery safety tests for your products, Energy Assurance is ready to help. We’re the premier independent battery testing facility in North America. Schedule a consult today to learn more about our safety testing capabilities and find the solutions you’re looking for.