As the battery market expands with the surge in EV battery manufacturing, it’s a good time to clear up some common confusion in battery terminologies.

Three primary terms are used to describe power storage devices in articles, reports, and spec sheets: “battery cell,” “battery module,” and “battery pack.” These are all related (but not interchangeable) phrases used to refer to fundamentally different levels of battery construction. Each one will also require unique styles of battery testing.

Definitions: Battery Cell, Module & Pack

These three terms describe increasingly larger units comprised of the previous units. Cells are stand-alone components, whereas a pack is a whole system. A cluster of cells creates a module, and a cluster of modules creates a pack. Here are some more specifics:

- Battery Cell — Cells are self-contained, component-level devices that convert chemical energy into electricity. This is the basic unit of a battery, consisting of a cathode, anode, separator, and electrolyte in a casing.

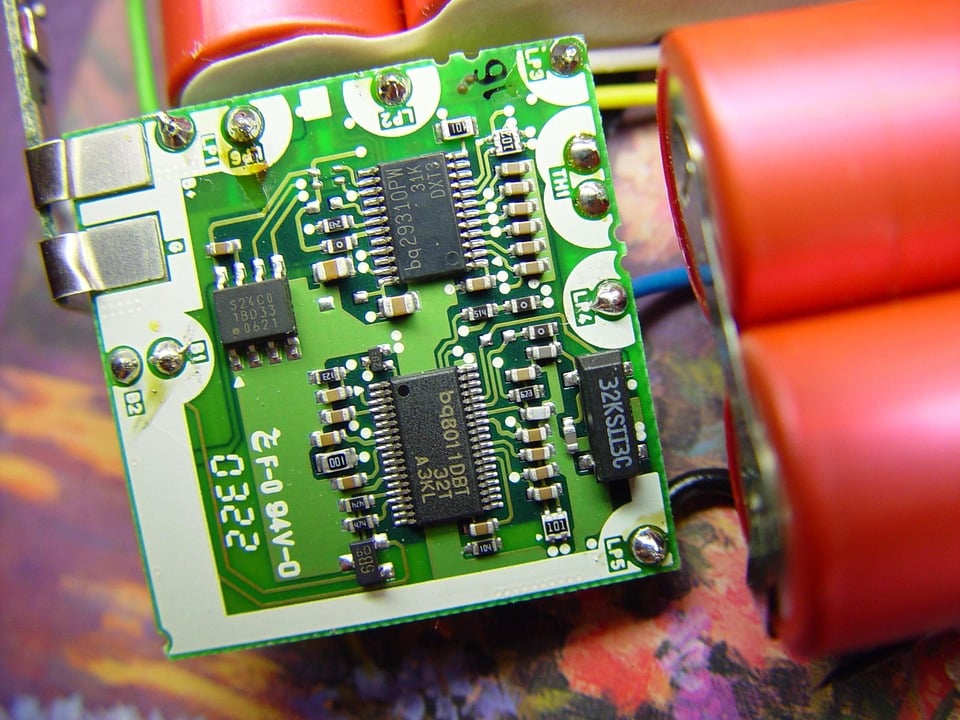

- Battery Module — As a sub-system level unit, a battery module contains any number of cells in addition to connectors, other electronics, or mechanical packaging. It is essentially a group of cells assembled together in a frame that protects them from shocks, heat, or vibration.

- Battery Pack — Packs are system-level units that may include multiple battery modules in addition to connectors, protection systems, a BMS (battery management system), cooling systems, mechanical packaging, and other related electronic components. This is a complete enclosure that delivers power to an end product (e.g. the battery system for an EV).

Testing Differences at Cell Level vs. Pack level

Battery cells, modules, and packs each require unique types of battery testing. Cells are essentially chemical containers, whereas a pack is a complex engineered system.

Therefore, you might test a cell to evaluate its chemical performance, but this wouldn’t make sense with a pack. The chemistries within the battery pack’s many cells should already have been tested and verified in advance of their selection for the pack application. Testing of the pack would focus more on system-level concerns (how the constituent parts work together).

- Battery Cell Testing — Cell tests focus first and foremost on measuring electrochemical performance in varying conditions. Stress, cycling, and environmental tests will investigate the cells’ overall output and efficiency in addition to the safety of internal chemical reactions. Your aim is to understand the dynamics and viability of the cell’s chemical reactions. Test sequences could include measurements of current, voltage, resistance, stability, and the rates of chemical reactions at different temperatures or in different environments.

- Battery Pack Testing — When testing a battery pack, the focus is less on internal cell dynamics and more so on engineering design of the system as a whole. Your testing regimen may include tests designed to answer engineering questions about durability, performance in specific use cases, application-specific safety, failure risks, and system-level interactions.

Battery cell testing will occur much earlier in the overall design and manufacturing process of a battery (or battery-powered device). The chemical properties of the battery concept must be validated before they can be combined into larger systems.

Modules and packs must go through sub-system and system validation where the goal is to verify that system engineering is sound and will meet all design specifications. By this stage of testing, the battery itself might even be a secondary focus as tests focus on the integrity of surrounding components.

Battery Testing Types

Battery cell, module, and pack tests may be looking for different things, but they’ll use many similar styles of testing to collect the needed data. Cycling tests, for example, could be used for testing both the efficiency of an individual cell’s chemical reaction in a hot environment and the engineering design of a whole pack in the same hot environment.

Several common battery test sequences include:

- Charge/discharge tests

- Battery cycling tests

- Stress tests

- Environmental tests

- Performance tests

- Competitive benchmark tests

- Product teardowns

- Battery failure analysis

- BMS data validation

For more information on these testing types and our battery cell, module, and pack testing capabilities, contact the Energy Assurance team today. We also invite you to download this free guide on Battery Cell, Module, & Pack Testing: The Basics for a closer look at your options and our services.