Frequently in the world of forensic analysis, one needs to be able to look inside a sealed device. This must be done without altering the device in any way as doing so might cause critical evidence to be lost. Two-dimensional x-ray provides some ability to internally image the device, but its level of detail is limited. Three-dimensional x-ray, better known as computed tomography or “CT” offers an answer.

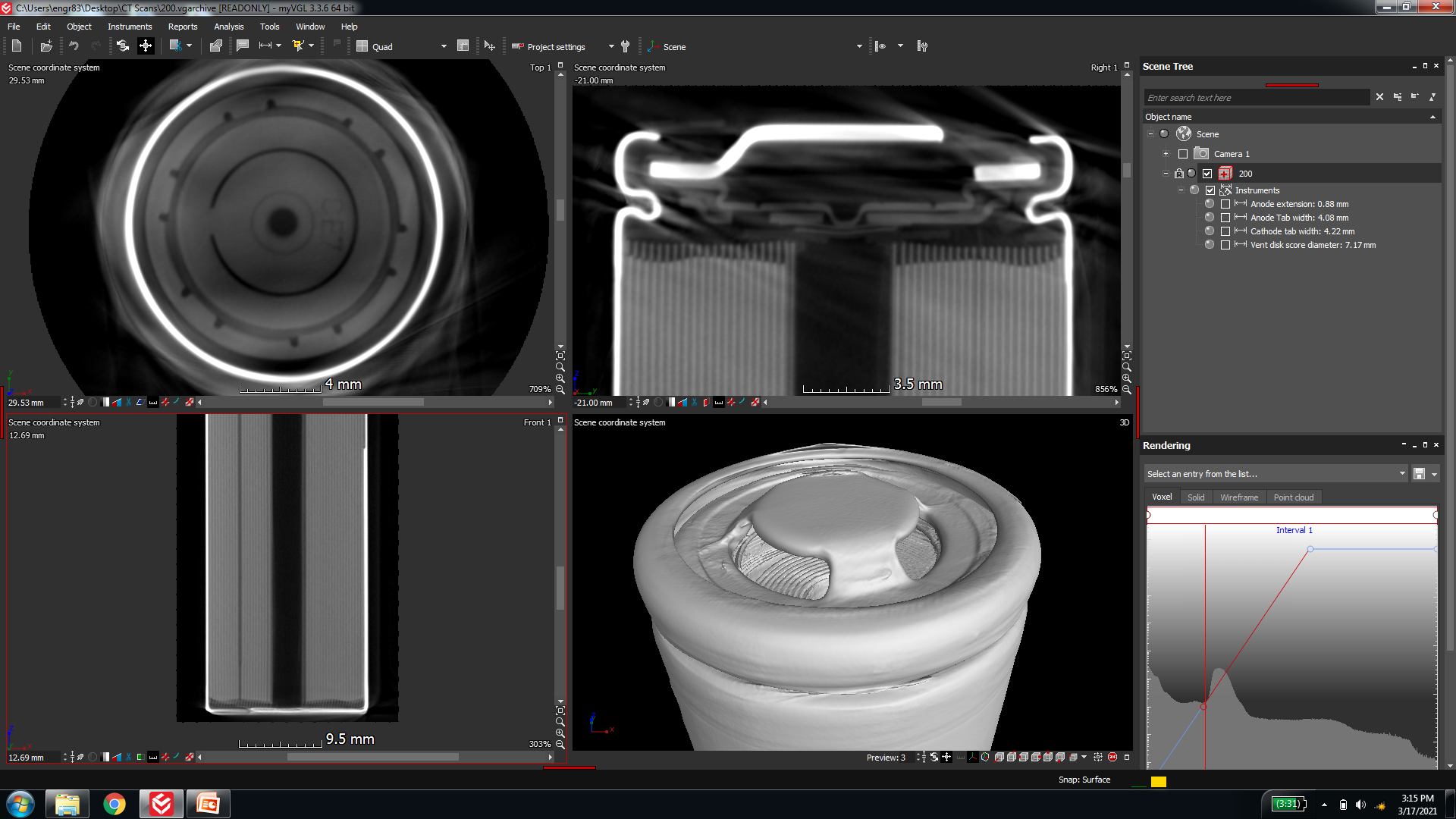

What exactly is computed tomography? CT is basically the process of taking multiple x-ray images and combining them together into a 3D point cloud. This allows visualization like you would see in a 3D CAD program and very accurate measurements of interior features of interest. This data is derived from grayscale images where the depth of shading is proportional to the relative density of the materials being scanned. This data can be colorized in software to make it more visually intuitive. Like most 3D measurement systems, it can also be directly compared with CAD design data to show differences between what was desired, and the actual part being evaluated. The following are some examples of what CT imaging looks like:

I was asked the other day if Industrial CT systems bear any resemblance to Medical CT systems. In conceptually how they work, yes, but in what they look like and the details of how they work, not so much.

Medical CT are sometimes referred to a “donut” as they are ring-shaped. The patient is reclined on a flat surface that is moved into a tubular housing that encloses the x-ray source and x-ray detector. The source and detector are mounted on opposite sides of an internal rotating ring that is moved around the patient. Additionally, the patient is moved through the ring to take x-ray “slices” which are later stitched together to image up to a full human body. Common medical systems are 128 or 256-slice capable. Here is an example:

Industrial CT scanners range from tabletop to very large systems. The very large systems involve much higher x-ray energy that can cause the products under evaluation to become radioactive. The systems used for cell and battery imaging are much smaller and do not negatively impact the products under evaluation when run using normal scanning parameters. Unlike the medical CT systems that rotate around the patient, most smaller industrial systems rotate the part with the x-ray source and detector not moving, or only moving in limited ways. Examples of such systems are shown below:

Tabletop:

Mid-Size (generally what might be used for most cells and small to mid-size battery packs):

Inside the lead-lined shielding box as shown above is the x-ray source (tube), a stage (articulating/rotating) for the product, and a detector. In some cases, like the one below, the distances between the source and sample, and the source and detector can be adjusted to optimize the imaging process.

Finally, the specific method that the CT system scans the part determines the level of detail and the associated cost:

- Quick scans of parts can yield valuable information at minimal costs. To further improve the efficiency, multiple parts can be held in a fixture and simultaneously scanned. Later through software, the single composite image is split into individual images of each sample for review and analysis. This method is particularly useful for screening processes.

- Longer duration scans of single parts can be used to provide higher resolution imaging of specific areas of interest within the part. This can also offer very precise measurements of mechanical features that would otherwise be inaccessible through manual disassembly.

- Helical scans offer the highest resolution. Here the part is slowly rotated and elevated simultaneously. Such scanning requires the most time to complete and thus comes at a premium price.

This article offers a high-level overview of what CT scanning can offer a trained forensic professional during the investigation of a suspect cell, module, or battery pack. When combined with other imaging techniques, in addition to electrical, mechanical, and chemical evaluations, the path to determining likely failure modes and root cause becomes less daunting. Energy Assurance offers both retrospective analysis of field failures as well as proactive safety reviews of energy products to aid clients in the assessment of risk. Contact us to see how our expertise can assist your team. When it comes to battery testing and analysis, you can rest assured with Energy Assurance!